Bio Mass in Oregon

Living plant material is the source of all biomass fuel. Oregon´s biomass resources include wood, agricultural crop residue and organic waste.

Oregon DOE says biomass can be used to produce liquid fuels such as ethanol and biodiesel, generate electicity, or create bioproducts such as plastics or adhesives.

Biomass uses plant or wood products like trees, wood chips, and yard clippings to generate electricity or produce heat. The Oregon Forest Resources Institute says about 15% of Oregon’s forestland have the potential to provide useful woody biomass through thinning. Fuel prices per kWh are lower for wood, says the Biomass Energy Center.

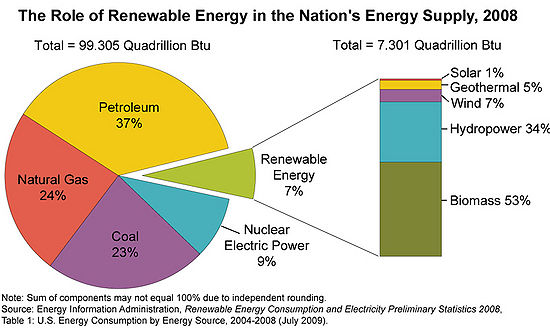

Governor Kitzhaber has unveiled biomass grants, through the Forest Products Energy Project, to develop the state's biomass industry. The existing biomass power generated in the United States, consists of approximately 11,000 MW of summer operating capacity, producing about 1.4 percent of the U.S. electricity supply.

The Oregon Department of Energy estimates that the total energy value of biomass fuel consumed in Oregon was 79 trillion Btu in 2003, about 10 percent of the total amount of non-transportation energy consumed in the state. Biomass supplies about 9 percent of all industrial energy consumed in the state.

Some mills use biomass fuel to generate electricity for on-site uses. Pulp mills burn the residual fiber and components of spent pulping waste to recover and recycle pulping chemicals and to generate steam. Pellets and fuel logs manufactured in Oregon and firewood collected from Oregon forests supply heat to homes.

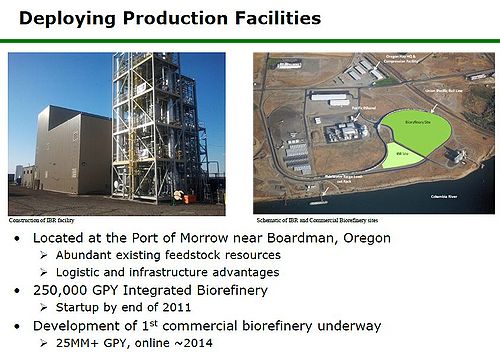

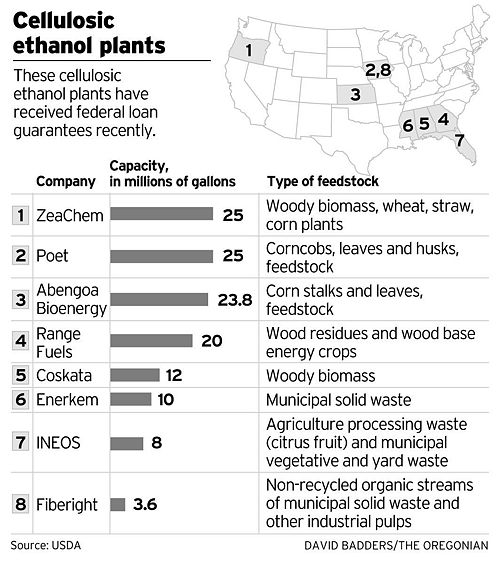

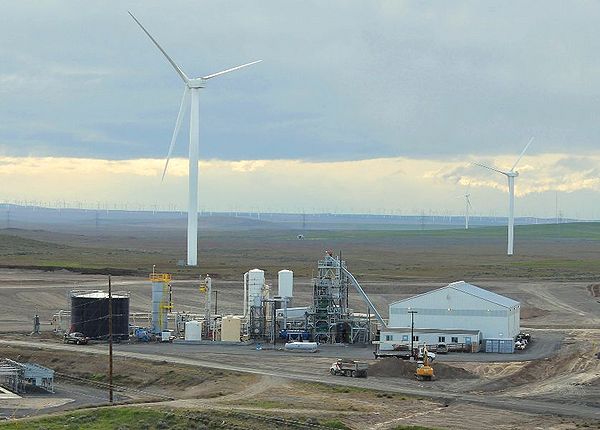

ZeaChem will construct a huge cellulosic biorefinery in Boardman, producing bio-based fuels and chemicals from woody biomass and agricultural residues. The company completed construction of a pilot facility and will ship the fuel down river on barges, through the Port of Morrow.

The new commercial-sized facility is expected to have capacity of 25 million or more gallons-per-year, adjacent to ZeaChem’s 250,000 GPY demonstration biorefinery.

Financed in part with a $235 million loan guarantee from the U.S. Department of Agriculture, ZeaChem, a Colorado-based energy company, expects the $390 million biofuel refinery will be producing fuel and valuable by-products by late 2014. ZeaChem must meet specified conditions before the 60 percent loan guarantee can be completed. Currently, Silicon Valley Bank is the bank of record for the project.

To break down biomass, ZeaChem uses a natural bacterium, acetogen, found in termites, cockroaches and other organisms. The bacterium ferments cellulose into acetic acid, which is made into ethanol. No carbon dioxide, a greenhouse gas, is produced in the fermentation.

ZeaChem will make fuel from a 28,000 acre poplar plantation in Boardman owned by GreenWood Resources of Portland. About 70 percent of ZeaChem's raw material will come from those trees. About 30 percent will come from agricultural residue, including feedstock, which costs about 50% less than Brazilian sugar cane and 80% less than corn based processes, says the company.

The Waste Management/InEnTec energy project at the Arlington, Oregon landfill converts municipal solid waste (household trash) into clean energy byproducts.

InEnTec, a Bend startup, converts landfill waste to gas. In October it landed a $22.5 million investment from Waste Management, and has recieved another $26 million investment, according to their SEC filing. InEnTec’s Plasma Enhanced Melter is the secret sauce. InEnTec's technology uses intense heat to change the molecular structure of waste into an ultra pure synthesis gas (syngas), which can be converted into clean energy fuels such as hydrogen, ethanol and biodiesel.

NEXT: Ethanol and Biodiesel in Oregon

Back to: Green industry <<